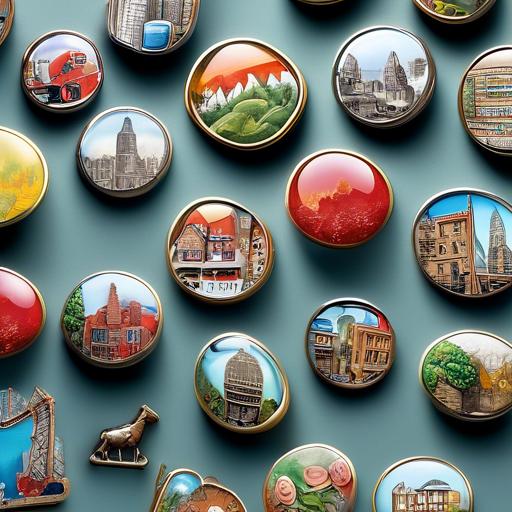

As a self-proclaimed pin enthusiast, I have always been intrigued by the process of creating enamel pins. From designing to production, there seems to be a certain level of mystery surrounding the craft. So, are enamel pins really as tough to make as they seem? In this article, we’ll delve into the world of pin-making to uncover the truth behind this popular accessory.

The Process of Creating Enamel Pins

Creating enamel pins may seem like a daunting task to some, but in reality, it can be a fun and rewarding process. The first step in making enamel pins is designing the artwork. This involves coming up with a unique and eye-catching design that will translate well into a small pin format. Once the design is finalized, it is indeed then transferred onto a metal mold, typically made of iron or brass.

The next step in the process is adding the enamel colors. Enamel, a type of powdered glass, is carefully added to each section of the design by hand. The pins are then fired in a kiln at high temperatures to melt the enamel and create a smooth, shiny finish. After cooling,the pins are polished to perfection and attached to a backing,ready to be worn and displayed proudly. while creating enamel pins may require attention to detail and craftsmanship,the end result is definitely worth the effort and can be a grate creative outlet for artists and designers.

Navigating Challenges in Enamel Pin Production

Creating enamel pins can be a fun and rewarding process,but it also comes with its fair share of challenges. One of the main obstacles in enamel pin production is ensuring the design translates well into a physical pin. Intricate details and small text can be difficult to reproduce accurately,especially when working with limited space. Additionally, selecting the right colors and finishes can also be a struggle, as certain shades may not appear as vibrant once the pin is manufactured.

Another challenge in enamel pin production is working with manufacturers to ensure quality control. Interaction is key in this process, as any misunderstandings or errors can result in a subpar final product. It’s crucial to regularly check in with the manufacturer to address any issues that may arise during production, such as color discrepancies or imperfections in the enamel. By staying on top of these challenges and working closely with your manufacturer, you can overcome obstacles and create high-quality enamel pins that you can be proud of.

Tips for Successful Enamel Pin Making

If you’re new to the world of enamel pin making, you might potentially be wondering if it’s a difficult process. while it can be challenging, with the right tips and techniques, you can create stunning pins that will impress your customers. Here are some :

- Choose the right design: A well-thought-out design is the foundation of a successful enamel pin. make sure your design is unique, eye-catching, and suited to the medium.

- Find a reliable manufacturer: Working with a reputable manufacturer is key to producing high-quality enamel pins. Do your research, ask for samples, and choose a manufacturer that meets your standards.

| Tip | Details |

|---|---|

| Use high-quality materials | Invest in quality enamel and metal to ensure your pins are durable and long-lasting. |

| Test different color combinations | Experiment with different enamel colors to find the perfect combination for your design. |

Choosing the Right Manufacturer for Your Enamel Pins

When it comes to creating enamel pins, finding the right manufacturer is crucial.With so many options available, it can be overwhelming to choose the best one for your needs. To ensure you get high-quality pins that meet your expectations, consider the following factors:

- Experience: Look for a manufacturer with expertise in producing enamel pins. Experience often translates to better quality.

- Quality of materials: Insist on using high-quality materials for your pins to ensure they are durable and long-lasting.

- Customization options: Choose a manufacturer that offers a variety of customization options, such as different shapes, sizes, and finishes.

Additionally, don’t forget to ask for samples before placing a bulk order. This will give you a chance to inspect the quality of their work firsthand.Remember, finding the right manufacturer may take some time and research, but it’s worth it to ensure you get enamel pins that meet your expectations.

Q&A

Q: Are enamel pins hard to make?

A: Making enamel pins requires meticulous attention to detail and some specialized equipment, but with the right tools and skills, it can be a rewarding and creative process.

Q: What materials are needed to make enamel pins?

A: Enamel pins are typically made from metal, enamel paint, and a clasp mechanism. Additional tools such as a kiln, mold, and polishing equipment may be required depending on the design and finish of the pin.

Q: How long does it take to make an enamel pin?

A: The time it takes to make an enamel pin can vary depending on factors such as the complexity of the design, the number of colors used, and the curing time for the enamel paint. On average, it can take several hours to a few days to complete a single pin.

Q: Can beginners try making enamel pins?

A: While making enamel pins does require some skill and experience, beginners can certainly try their hand at creating their own designs. Starting with simpler designs and practicing basic techniques can help beginners build their skills and confidence in pin making.

Q: Is it expensive to make enamel pins?

A: The cost of making enamel pins can vary depending on factors such as the materials used, the complexity of the design, and the quantity produced. while there are upfront costs for equipment and materials, making enamel pins can be a cost-effective way to create unique and personalized accessories.

Wrapping Up

while enamel pins may seem like a complex and daunting undertaking, with the right guidance and resources, they can actually be quite achievable for those with a creative spirit and a passion for design. Whether you’re looking to start your own pin business or simply want to create a unique accessory for yourself, don’t let the perceived difficulty deter you from pursuing this fun and rewarding craft. With a little patience and practice, you can master the art of making enamel pins and add a personal touch to your wardrobe or business. So, roll up your sleeves, get those creative juices flowing, and start creating your own custom enamel pins!